Euro groove

Giesse is the European Groove specialist, the concept that forever changed the aluminum window industry. The Euro Groove is still the first choice amongst installer all over the world.

European Groove history

Up until the ‘70s aluminium windows were treated as though they were sections of wood: milling-cuts on profiles was the norm, double stop gaskets were used along with simple accessories and no perimetral locking. Between the ‘70s and the ‘80s research for better performance, simpler processing, and improved technology in hardware and seals, led extrusion manufacturers towards a shared standard. The Euro Groove is the natural result of this evolution.

What is the European Groove?

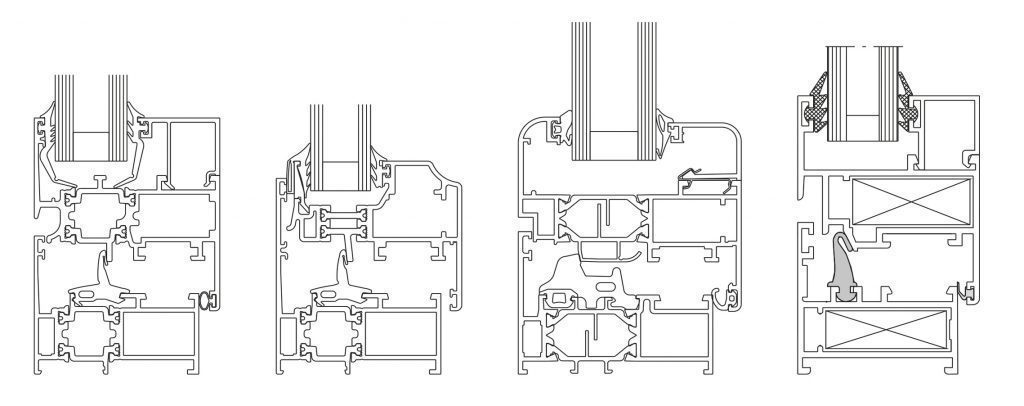

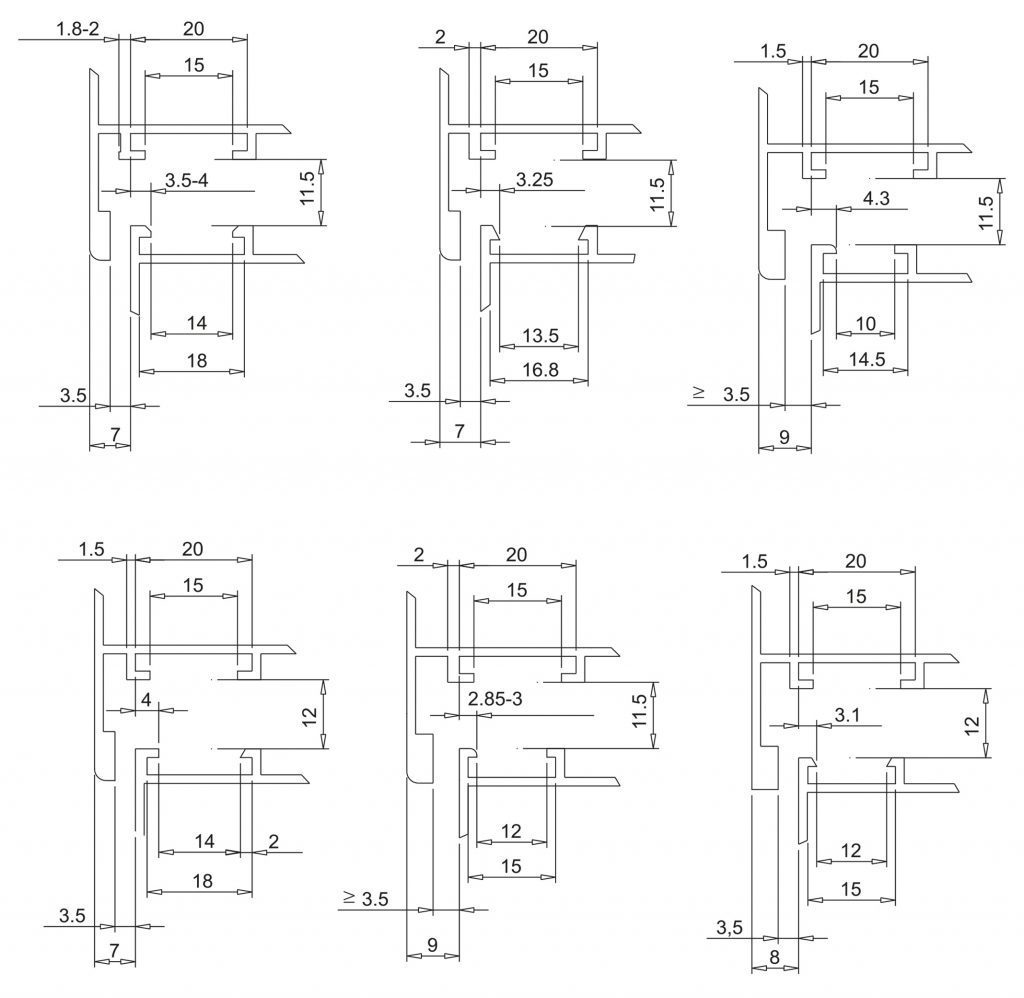

The Euro Groove is a sash-frame profile system, with a specific configuration that allows the fixing of clamp hardware.

It is the sum of dimensions that are commonly accepted and recognized as a standard in the aluminium windows sector. Benefits of Euro groove include:

- Quicker accessories mounting

- Quicker processing and reduced costs

- Higher performance against air, water and wind

Why is European Groove better?

Today Euro Groove is the most popular system in the world for profile systems with clamp accessories. It was chosen by the main international players as the gold standard to achieve high performance. The best efforts in research and development are led by European Groove system solutions.

The Euro Groove offers a series of benefits for the installer.

Minimal profiles

Its characteristics of durability and versatility make aluminium the perfect material for minimal windows and doors, even for large openings. The CHIC concealed hardware and SUPRA7 minimal handle allow you to create minimalist windows and doors while still guaranteeing high level performance.

Easy to install

The standard groove allows the insertion of the connecting rod and all the elements needed to fit every kind of different opening type. The polyamide rod optimises production, connects all components without the need for cumbersome machining and enables the movement of the cremone to be transferred to the locking points. The accessories can be pre-assembled and can be installed without special machining. Furthermore, it is possible to add locking points on the entire perimeter of the window.

Solutions

The standardization of the European Groove allows for a greater variety of technical solutions and products configuration possibilities available for windows and doors of any kind and dimensions (different shapes, different finishes, different accessory levels).

Best performance

The open joint gasket replaces the double hinged gasket, guaranteeing a better perimeter seal and therefore a better water, air and wind tightness performance and also a higher acoustic insulation. The force exerted by the pressure difference between the inside and outside of the chamber ensures perfect contact of the central seal, improving the watertightness and allowing continuous drainage through the drainage holes.

Lower profile costs

Milling/machining to fit the window profile is no longer necessary. The standardisation of machining operations with punching machines makes it possible to dispense with milling, e.g. for easy, fast and secure fastening of the cremone on the profile.

Less investment in warehouse stock

Thanks to the Giesse polyamide rod cut to size, there is no need for specific kits for each leaf size.

With just the basic kit of CHIC, Futura or Classic tilt-and- turn and some complementary accessories it is possible to to create any size of window or door. There is also no need for dedicated assembly tools.

Sustainability

Increased environmental sustainability through manufacturing processes and installation destination. Aluminium production now makes use of recycling applied on a large scale, which greatly reduces CO2 emissions to the environment and saves 95% of the energy needed to produce new aluminium.